This investigation, shortlisted in the RIBA President’s Awards for Research, looks at replacing man-made panels with plant-based material to return dwellings to appropriate, breathable products that are resilient to regular inundation

Fantasy Island rests on the Amazonian Trapezium, where Brazil, Peru, and Colombia meet. Like many rapidly formed riverine terrains, this alluvial island is experiencing unprecedented inundation transformations. Records from this past decade point steadily towards climate change as the primary driver for seasonal pattern shifts and rise in extremes.

Housing in the region traditionally relied on plant leaves. The thatched palm was the primary cladding material for distinctive expressions of a continuous roof-wall, which provided climate comfort. Nevertheless, the ideologies and funding introduced in the mid 20th century promoted industrial panels, particularly galvanized zinc. The unsuitability of these panels is multifold, including heat entrapment, toxicity, and cultural inadequacy, demanding radical material reinvention. Dampness and decay make building enclosures the primary incubator for indoor contamination by harbouring pathogens, so controlling the porosity and surface conditions of enclosure materials is vital to prevent moisture and deterioration during and post-flooding and from excessive indoor humidity – which is widely prevalent globally, including in the UK.

Fused Deposition Modelling (FDM), a 3D printed extrusion without UV exposure or chemical binders, offers unique opportunities to reuse plant waste to make flood resilient enclosures and open paths for material craft reclamation. But are FDM products scalable and resilient to the increasing challenges of inundations? This investigation hypothesizes that FDM enables transformative advantages for flooding and health resilience through building enclosures made exclusively of plant-waste composites with structural capacity and moisture and water resistance.

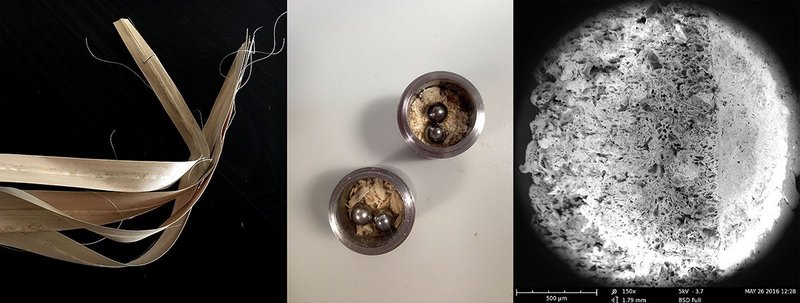

To assess this statement's validity, an extensive ethnographic and typological investigation was combined with experimental research developed from the nano to wall scale on FDM composites made from three major plant waste compounds – palm, bamboo, and cork (Figure 1). This investigation is the first-ever physical testing of FDM plant waste composites from the nano to wall scale in water/dry cycles. The quantitative study is informed by an integrated qualitative typological and ethnographic analysis of Fantasy Island's enclosure technologies as a representative case for sites under severe environmental pressures of climate change.

Three primary intertwined challenges are involved in natural materials innovation for flooding risk enclaves: building-scale simulation models, flooding resilience models, and FDM large-scale limitations. Current flood risk simulation models for building scale lack the capacity to integrate specific material data and are geared towards industrial systems and synthetic materials. We must also interpolate flooding risk simulation to material property data to inform and support FDM control mechanisms that influence structural and humidity and water sorptivity. By optimizing control parameters and mixtures, we can radically improve the quality of surface roughness, porosity, particle and fibre distributions, making plant-based products resilient to flooding and potentially economically advantageous.

Extensive mechanical testing was applied to determine strength, stiffness, deflection, capillarity, water and moisture sorptivity. The investigation included water tank experiments, which comprised sensing and IR imaging to measure capillarity and sorptivity (Figure 2-left) and deflection (Figure 2-right). The mechanical tests were supported with imaging analysis at the nanoscale (transmission electron microscopy), at the micron scale (scanning electron microscopy and x-ray computed tomography) of porosity and surface conditions, and large-scale water tanks. Experimental research results on the palm, cork and bamboo composites confirmed a diverse impact on material properties post-FDM across scales. For example, the average porosity in bamboo composites was 22% versus 14% in cork. The deflection and capillarity in the water tanks for cork and PLA-PHA composites were minimal – below 0.2% – showing strong promise for real flooding application.

Using outputs from the experimental and ethnographic findings, I developed a multiscale model that allows the user to visualize and create material merit indices. The model was designed for a simple interface with available flood risk models for micro-level models that lack material specificity. The multiscale model can be incorporated into available flood risk analysis platforms (for example, Amirebrahimi’s ‘material package’) to evaluate the flood resilience of a particular building enclosure material. The multiscale model developed in this investigation supports optimizing surface roughness, porosity and particle density to overcome critical scalability gaps of natural material compounds in FDM. The model enables the control build parameters for recycled plant waste panels with functionalized properties through a simple translation of material value criteria across lengths of scales.

This investigation's primary contribution is to advance the knowledge and capability to innovate natural waste reuse through extensive multiscale experimental studies evaluating the implications of FDM in architectural scale applications. The research also encompassed developing the first material-specific flood resilience model designed for emerging technologies, enabling interpolating quantitative and qualitative data. The multiscale experiments and model supported the development of parameter optimization protocols for open-source codes that address key scalability hurdles to bring into fruition a new generation of 3D printed plant-based materials with flooding resilience, which can transform the capacity for material craft reclamation in the Amazon and other frontiers.

Fantasy Island: The other Amazon by Maria Paz Gutierrez, of the Centre for Natural Material Innovation at the University of Cambridge, was shortlisted for the President’s Awards for Research 2020

Further reading

Amirebrahimi, Sam, Abbas Rajabifard, Priyan Mendis, and Tuan Ngo. 2016. 'A BIM-GIS Integration Method in Support of the Assessment and 3D Visualisation of Flood Damage to a Building.' Journal of Spatial Science 61 (2): 317–50

Gutierrez, Maria Paz. 2020. 'The Northwestern Amazon Malocas: Craft Now and Then.' Journal of Material Culture 25 (1): 3–35

Martin Brañas, Manuel, and Iman Torres. 2014. 'Análisis Térmico de Dos Tipos de Techo Usados En Las Viviendas Rurales Amazónicas' 23 (2): 105–18.

See the other winners of President’s Medals and President’s Awards